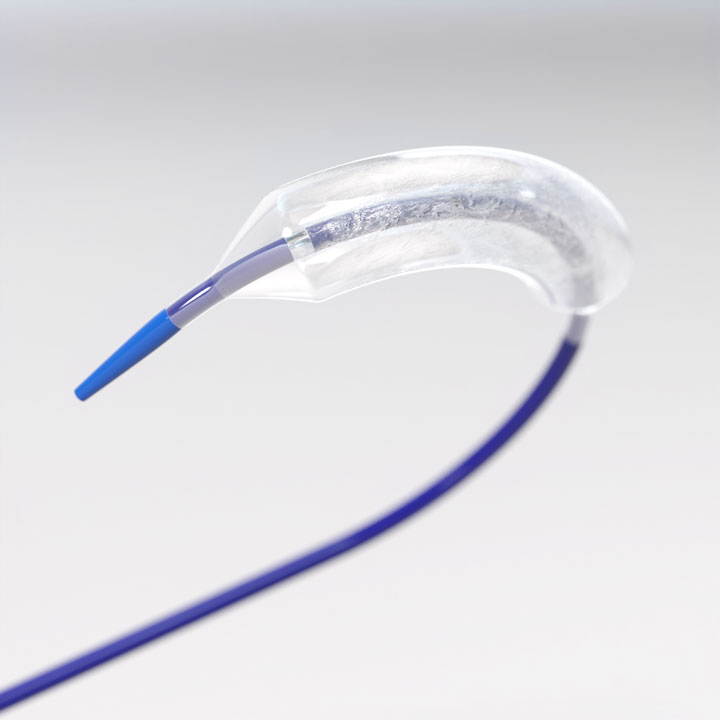

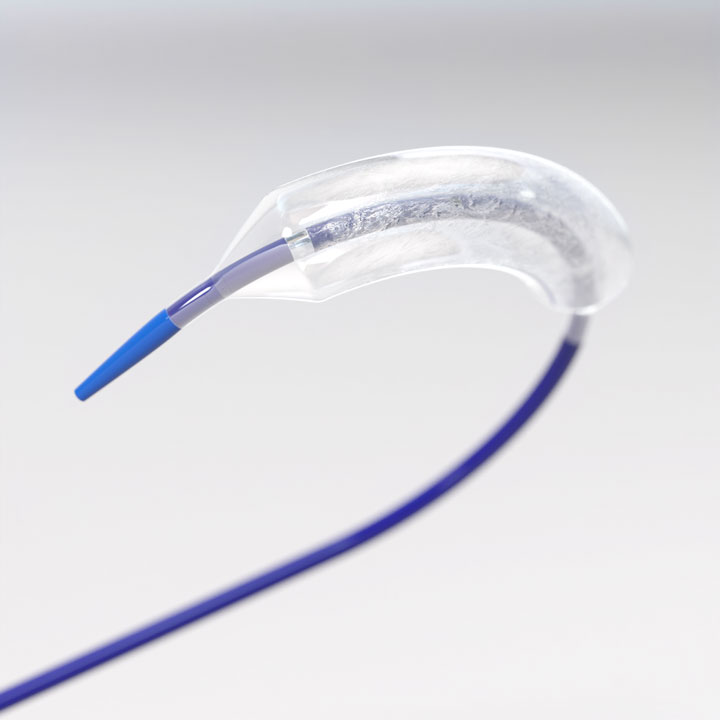

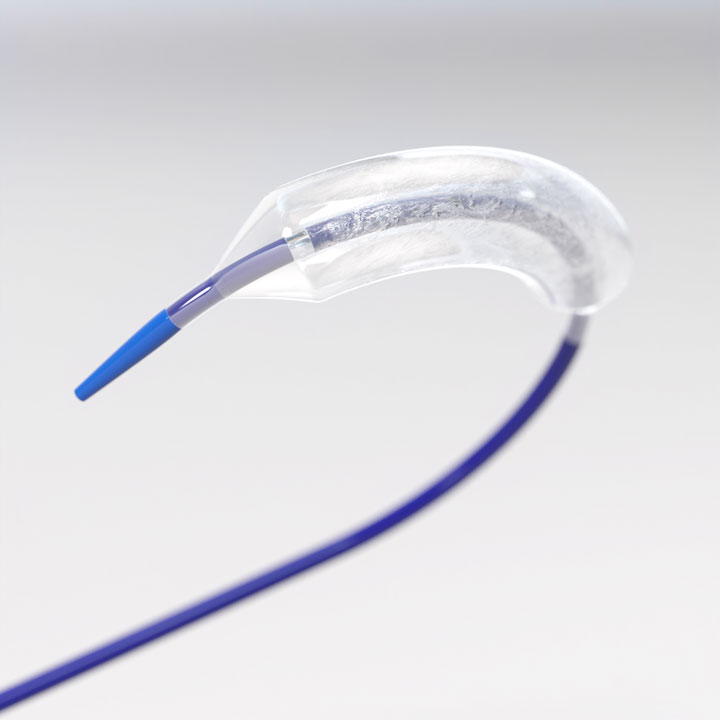

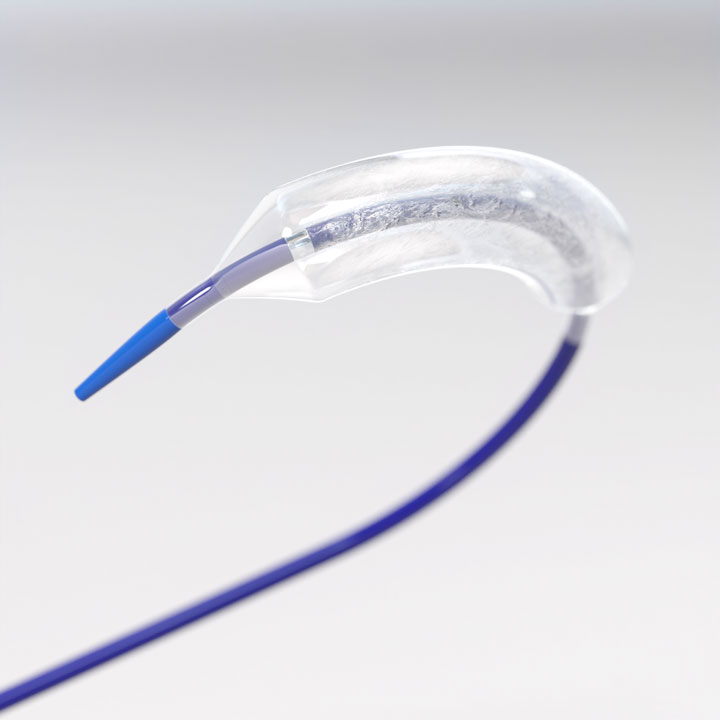

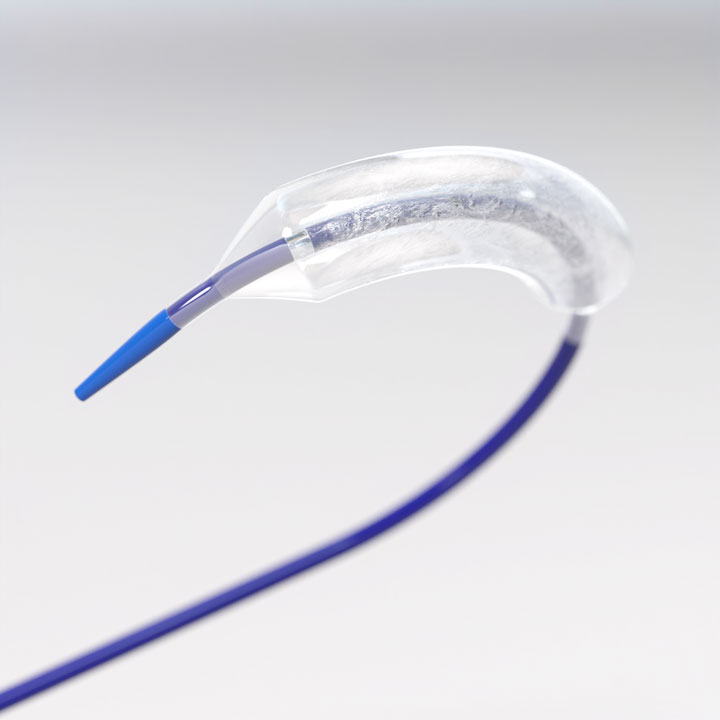

球囊导管解决方案

Description

The “Workcell” is an automated platform designed to improve the quality, speed and cost of multiple balloon catheter and stent delivery production processes.

MSI’s patented balloon catheter pleating and folding equipment has been reconfigured to allow pleating and folding processes to occur simultaneously to significantly reduce takt time. A new automated sheathing process ensures folded balloons are carefully loaded into protective sheaths without risk of twisting or damage.

The system also features industry leading stent positioning capabilities so stents are accurately aligned between marker bands. The system can be configured with standard or film integrated stent crimping heads to protect drug coatings from damage and contamination.

Inspection stations such as stent positioning and leak testing can be incorporated without affecting takt times. 100% quality inspections with batch record storage provides confidence that all products met output criteria.

Catheters are oriented vertically to significantly reduce floor space required. It is estimated that the standard configuration of these machines would require over 25 linear meters of manufacturing floor space. The Workcell can squeeze all of these processes into 2m2 machine.

Full size 350mm Pleat and Fold heads and 120mm Crimp heads are accommodated for on the Workcell platform.

Workcell Features:

Single operator can run multiple production processes

Parallel processes run simultaneously to optimize takt time and production output

Vertical product handling reduces equipment footprint

Integrate quality inspections without impact on takt time

Automated product handling increases consistency of finished product

Customize configuration to meet the needs of your unique process

Rotary Index table from 4 – 12 stations configured

to meet your needs.

10 Station Example Configuration

Load/unload

Load/unload

Initial Inspection w/ Keyence Laser Micrometer and Barcode Verify

Pleat w/ unique geometry using WavePleat Technology

Pleat w/ unique geometry using WavePleat Technology

Fold w/ 250mm Head using WavePleat Technology

Autosheathing with Patented Process

PreCrimp w/ Stent Positioning

Final Crimp w/ Hybrid Film Head

Final Inspection w/ Cognex Vision and Leak Testing