Bracket crimp expertise and equipment

Machine Solutions is the original inventor of the revolutionary bracket crimping technology. This technique is a proven method for crimping balloon-expandable stents, loading self-expanding nitinol stents, and crimping living tissue valve beds in the catheter lab. Our equipment has been used to manufacture millions of life-saving devices around the world.

Bracket crimp

Machine Solutions is known worldwide for our stent crimping technology, which has become the industry standard for crimping bare metal stents, drug-eluting stents and next-generation polymer stents.

Automatic stand crimping work unit

Machine Solutions is a global leader in bracket crimp automation. Our "Work Cell" technology combines 10 separate processing stations into one integrated machine to increase productivity and reduce labor costs. The system features industry-leading bracket positioning so brackets are accurately aligned between marker bands. The system can be configured with standard or film-integrated stent crimps to protect the drug coating from damage and contamination.

Work unit features:

One operator can run multiple production processes

Parallel processes run concurrently to optimize takt time and production yield

Vertical product handling reduces equipment footprint

Bracket crimping equipment

MSI's bracket crimping equipment has become the industry standard for manufacturing most approved brackets and brackets. All of our bracket crimping equipment emphasizes user control and repeatability, with a robust PLC control system that automates repetitive steps with minimal operator dependence.

By using best-in-class materials and equipment to produce our machines, our automation platform increases throughput, increases throughput, and reduces cycle times and costs. We also provide the best customer support by providing quality inspection reports and software validation and documentation.

Machine Solutions offers a variety of bracket crimping machines such as:

Drug-coated stent crimp

automated work cell

Bench Bracket Crimp

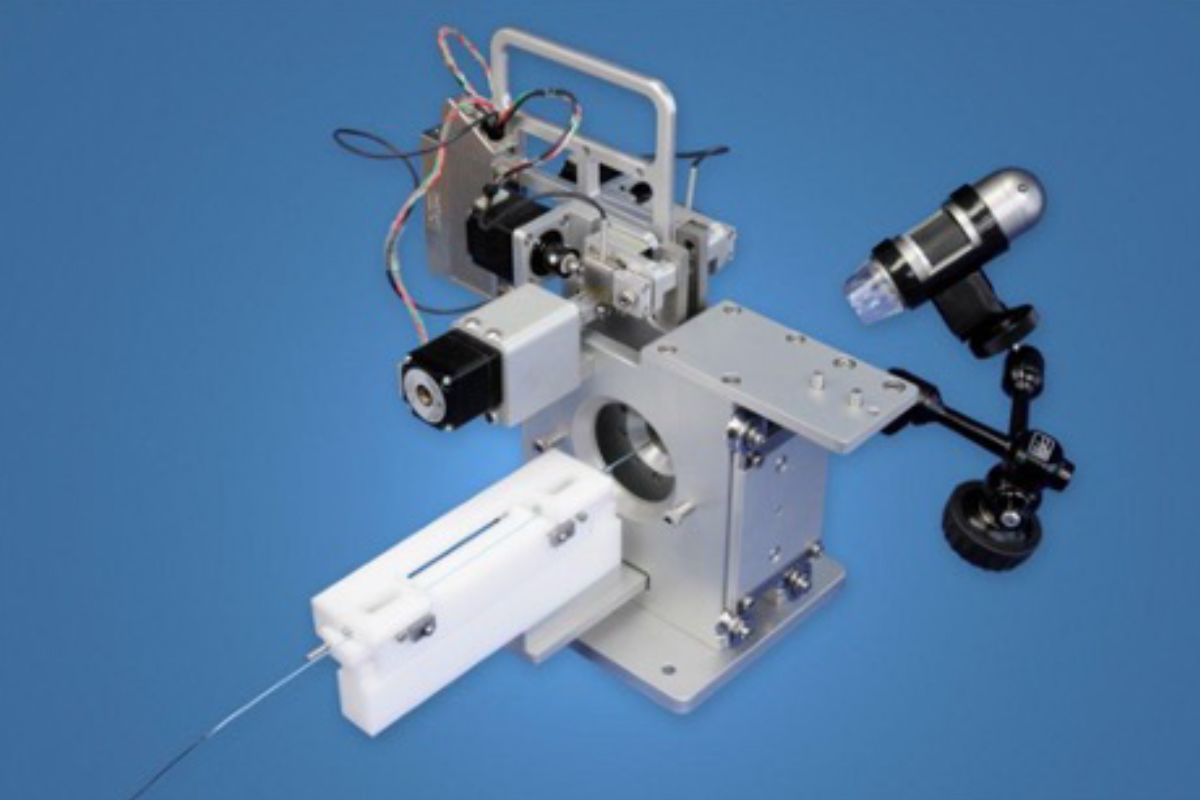

R&D/Pilot production bracket crimping

Bracket Loading Solutions

MSI's superior stent loading device uses segmented compression technology to reduce the diameter of self-expanding stents. Our powerful equipment is used by manufacturing companies around the world, from R&D applications to fully automated manufacturing equipment. With an automated platform, our stent loading equipment provides medical device manufacturers with a more efficient process by increasing throughput, increasing throughput, reducing cycle times and costs.

Our wide range of rack loading equipment includes:

Automatic rack loading

R&D stent loading

Handheld Bracket Crimping Tool

Disposable Heart Valve Crimp Tool

Heart valve crimp

MSI's Heart Valve Crimp Tool uses a proprietary segmented compression technique to reduce the diameter of large stents with living tissue attached. These tools are available in a variety of lengths and diameters and can also be customized for use in a variety of catheter labs around the world.

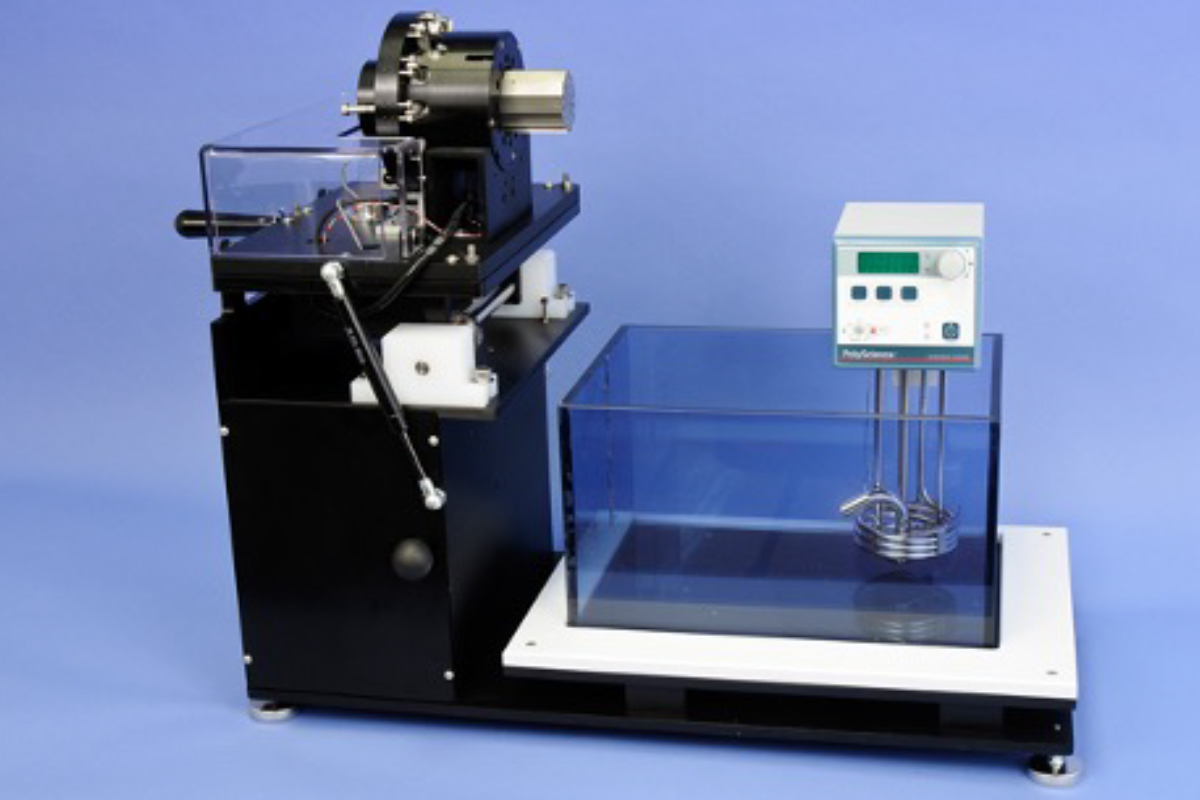

Radial force test

Machine Solutions Radial Force Testing Devices are specified in ASTM Standard F3067 – 14 Radial Loading Guidelines for Balloon-Expandable and Self-Expanding Vascular Stents as the device of choice for collecting radial or hoop forces from stent-like devices. MSI's patented compression technology is used to compress cylindrical stents and measure diameter change and hoop force. This provides properties including radial stiffness and strength, chronic outward forces during expansion, and radial reaction forces.

Bracket Fixing Test

Machine Solution's stent testing equipment has been shown to produce the most reproducible results compared to the tape and spacer method. Our self-calibrating system limits operator usage so test results are not compromised, reducing the number of samples required to obtain statistically significant results. The device can be used for regulatory submissions, competitive product testing, R&D equipment evaluation, and online manufacturing quality assurance. Our bracket testers provide direct feedback on how adjustments to crimp parameters affect bracket fixation results, allowing R&D engineers to quickly optimize crimp process settings.