Industry leading catheter detonation equipment

As a global leader in catheter dumping equipment, Machine Solutions offers innovative technologies for all of your catheter tip solutions, including catheter tip forming, bonding, flaring and flanges. Conduit beveling, also known as end forming, is the process of forming the end of a thermoplastic tube using a thermally conductive mold.

The process of thermoforming the distal end of the catheter into the desired round or tapered shape requires heating the mold to a specific temperature and then inserting the shaft material a certain distance. With our superior heating technology and thermal profiles, our equipment is proven to produce precise, high volumes at low cost. All of our equipment is safe, easy to use, produces high-quality parts quickly, and can be customized to meet throughput needs and integrate with automation platforms.

Tip

Today's catheter delivery systems rely on increasingly complex shapes, structures and polymers to deliver the desired treatment. The complexities of many catheter dumping and tip forming applications can only be consistently achieved with advanced technology and the correct application of sound engineering principles.

Vante and PlasticWeld Systems equipment is the global standard for flip-chip and end-forming equipment. Superior heating technology, proprietary thermal analysis and a clear customer engagement process led by our experienced engineers - ensure you get the best results.

Increase throughput and reduce cycle times: 4 products at a time

The Onyx system combines the production capacity of up to four (4) independently controlled Vante dump stations into a compact desktop platform that can be supported by a single operator!

Advantages of Conduit Dumping Equipment

Vante and PlasticWeld pouring solutions are designed for circuit board-up conduit fabrication. The system consists of an RF generator (power supply), forming/welding platform and custom tooling specific to your application. Our equipment is capable of processing all thermoplastics to create a variety of tipping, welding and forming molds for any application.

Our equipment advantages:

Closed Loop Temperature Control - Better Process Control and Yield

Small hot zone - ideal for producing small, flash-free parts

Embedded heating coils – no setup time when changing molds

Low quality molds - reduce cycle time

Small Footprint - A compact benchtop machine that can be integrated with an automation platform.

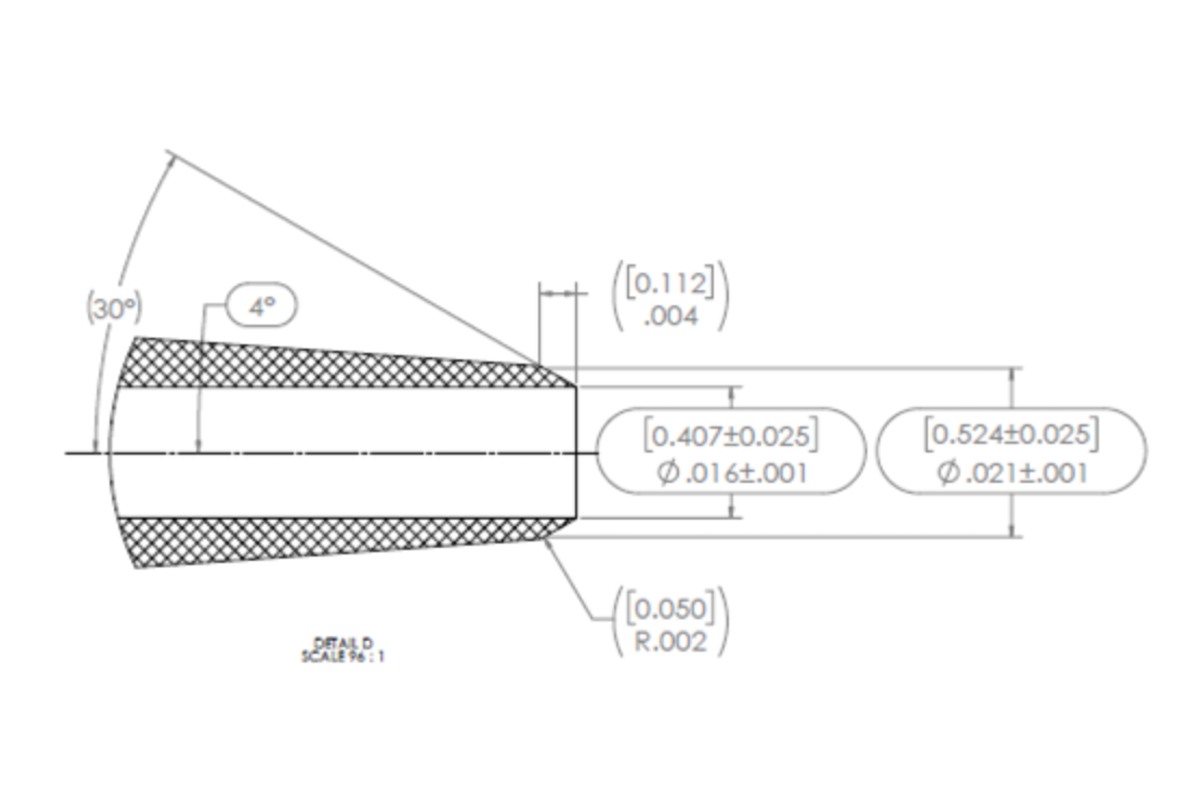

Conduit tilt dies certified to meet your specifications

We specialize in the design and production of cutting edge forming molds to meet your production requirements. Mold production begins with the selection of high-quality alloys. State-of-the-art CNC equipment is used to produce our precision tipping molds.

We don't just provide metal hardware; our process provides parts that meet your specifications and support your verification activities. Our team of engineers certifies over 300 tools each year and can apply their expertise to optimize your product.

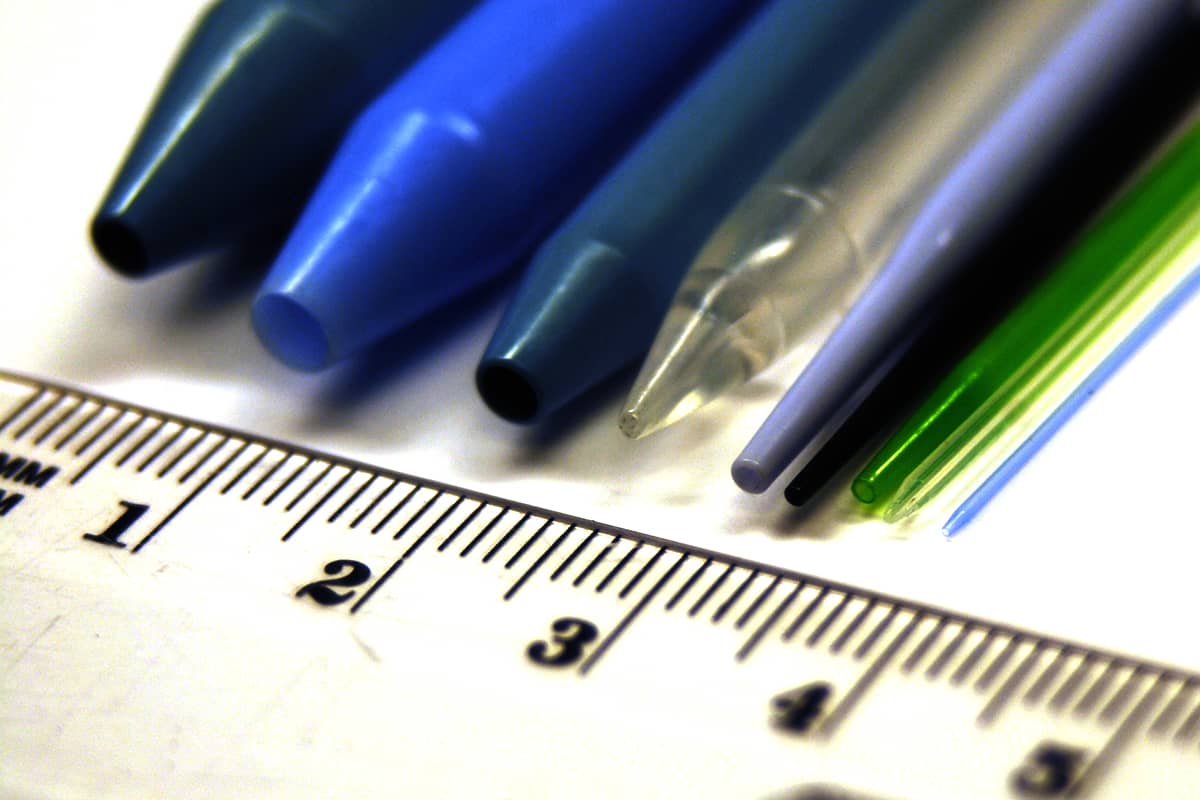

Prototype sample of catheter tip

Machine Solutions recognizes that the market requires rapid production of prototype components to prove design concepts and secure high-volume production projects. Our goal is to get into your hands initial proof-of-concept samples that represent our capabilities and are close to the final geometry required for your project. We have invested in dedicated manufacturing, design and engineering capabilities focused on delivering the fastest possible sample production for our customers.

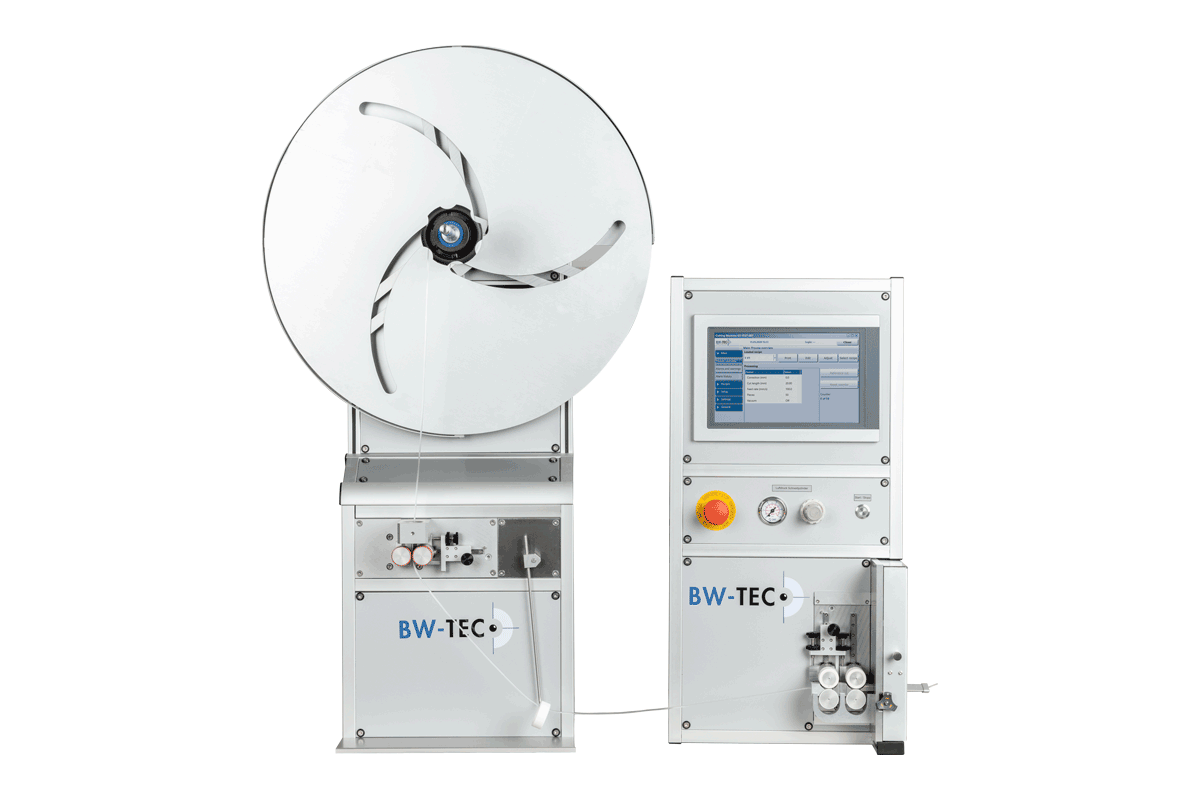

New BW-TEC Automatic Medical Tube Cutting Machine

Get the best results with the BW-TEC automatic medical tube cutter. The unit features adjustable spool clamps, axial cutting dies, optional vacuum system and standard cutting blades for efficient and economical!

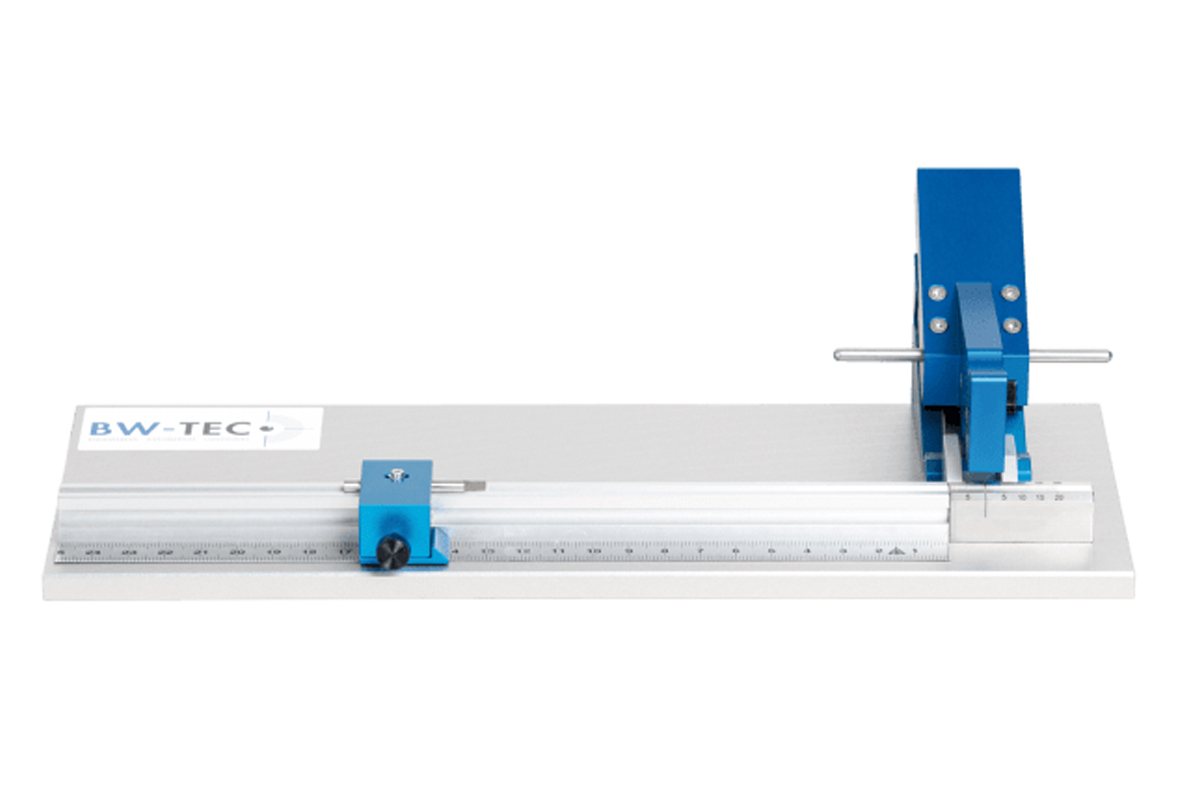

Simple pipe cutting jig

Machine Solutions offers simple tube cutting jigs that provide clean ends for precision pouring and bonding processes. For this simple fixture, the cutting head is mounted on a precision linear slide. Industrial cutting blades supported by product V-rails with cutting slits produce perfect rectangular cuts. Adjustable stopper ensures repeatable length.